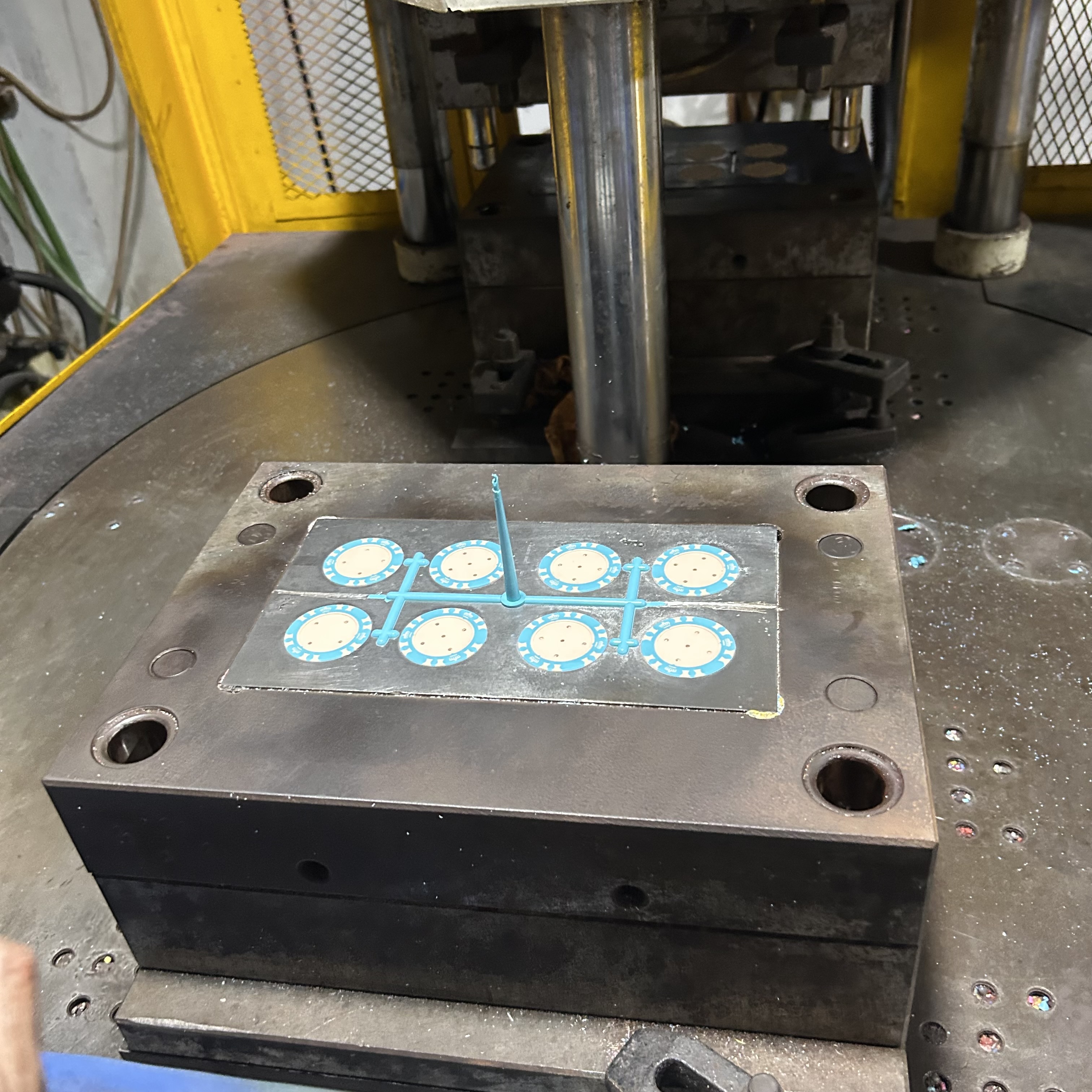

The creation of clay pieces requires meticulous craftsmanship to ensure quality and aesthetics. One of the innovative methods used to create these pieces is to use double-injected metal plates to achieve the desired effect.

The first injection of the metal plate is crucial as it determines the base color of the chip. This foundational step sets the tone for the final product, allowing for a variety of colors to be used in subsequent stages. Once the base color is determined, the second injection is made. This step is particularly important as it allows for multiple colors to be incorporated into the design. Chips can be injected multiple times, adding different shades or patterns each time, resulting in a vivid and visually appealing final product.

Once the injection process is complete, the next step is to apply stickers to the chip. These stickers can feature intricate designs or branding elements to enhance the overall look of the chip. This step is essential to add a personalized element and ensure that the chip stands out in the market.

Once the chip design is finalized and the label is applied, it undergoes a thorough sealing and packaging process. The plastic seal is used to protect the chip from damage and contamination, ensuring that the chip is intact before it reaches the consumer. The packaging is carefully designed to maintain the integrity of the product and provide an aesthetically pleasing appearance.

In summary, the production of clay chips is a complex process that combines innovative technologies such as metal sheet double injection molding, sticker pasting, and meticulous sealing packaging. This multi-step approach not only enhances the visual appeal of the chips, but also ensures their quality and durability, making them a popular choice in a variety of applications.

Come and customize your chips now.

Post time: Jan-04-2025